UB Model

ABOUT MACHINE

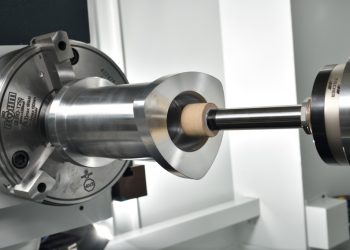

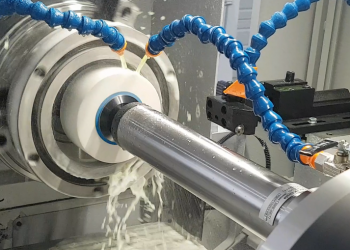

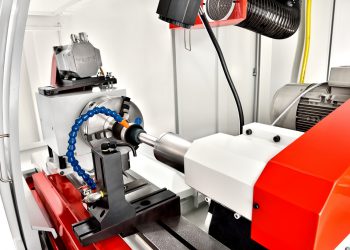

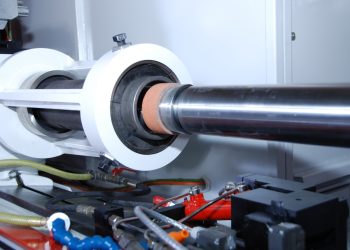

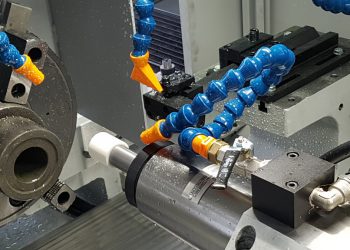

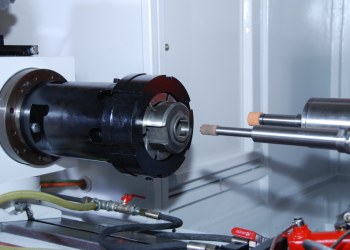

“UB” model is internal cylindrical grinding machine specially intended for grinding of deep holes. It is mainly suitable for small batch production, i.e. for cylindrical and taper internal grinding, internal and external face, grinding of blind and through hole. This model is derived from basic models of external grinding machines “BS”, by placing internal grinding spindle on the wheelhead. Internal grinding range starts from od Ø10 – Ø600 mm, hole grinding length up to 1200 mm. The hole diameter and length ratio is the most important detail when choosing an adequate machine model.

The model is available in NC and CNC option. Usually, it is not used in configurations with turret wheelhead, due to lack of space inside the enclosure. The most common configuration involves setting the belt driven internal grinding spindle and changing the corresponding spindle in accordance with the dimensions of the work part to be ground. If the replacement spindle has a smaller diameter, mounting is done by placing the reducer sleeve in the spindle holder. Characteristic for this model is the selection of the workhead with higher torque and placement of the steady rests, in order to maintain geometry of the work part during grinding.

ADDITIONAL OPTIONS

- Workhead make with increased accuracy

- Spindle installation of increased power and torque

- Special tooling for clamping related to different technical tasks

- FINILIFT system with air cushions for easier movement of workhead

- Manual and automatic closed steady rests with retractable arms and fine adjustment

- Gap-crash system for collision control and higher safety

- In-process, Post-Process gauging, touch probe for part axial positioning

- Crane for easier and safer component loading/unloading

- Prisms for work part clamping

- Remote diagnostic for immediate support and quick service

- Machine compatibility with Industry 4.0

| Technical data | UBC | UBD | UBE | ||||||

| Min./max. Grinding diameter | 10/300 mm | 20/400 mm | 50/600 mm | ||||||

| Max. workpart diameter | ø350/ø450 mm | ø350-ø800 mm | ø800 mm | ||||||

| Max. grinding length | 600 mm | 800 mm | 1200 mm | ||||||

| Max. workpart weight (incl. chuck head) | 100 kg | 150 kg | 500 kg | ||||||

| X-axis – Wheelslide | |||||||||

| Max. travel | 380 mm | 460 mm | 650 mm | ||||||

| Max. speed | 6000 mm/min | 6000 mm/min | 3000 mm/min | ||||||

| Linear scale resolution | 0,0001 mm | 0,0001 mm | 0,0001 mm | ||||||

| Servo motor power | 1,48 kW/6 Nm | 11 Nm | 27 Nm | ||||||

| Z-axis – Table movement | |||||||||

| Max. travel | 2150 mm | 3150 mm | 3250 mm | ||||||

| Max. speed | 7000 mm/min | 6000 mm/min | 5000 mm/min | ||||||

| Linear scale resolution | 0,0001 mm | 0,0001 mm | 0,0001 mm | ||||||

| Servo motor power | 16 Nm | 27 Nm | 48 Nm | ||||||

| Wheelhead | |||||||||

| Max. spindle accepting hole | ø120×230 mm | ø120×230 mm | ø140×230 mm | ||||||

| Max. spindle speed | 40000 rpm | 40000 rpm | 24000 rpm | ||||||

| Max. spindle power | 7,5 kW | 11 kW | 15 kW | ||||||

| Workhead | |||||||||

| Speed range | 0,1-500 rpm | 0,1-450 rpm | 0,1-400 rpm | ||||||

| Spindle bore | 38 mm | 38 mm | 54 mm | ||||||

| Fitting taper | MT4 | MT5 | МT6 | ||||||

| Swiveling range | 0°-90° | 0°-90° | / | ||||||

| Motor power | 11 Nm | 11 Nm | 48 Nm |