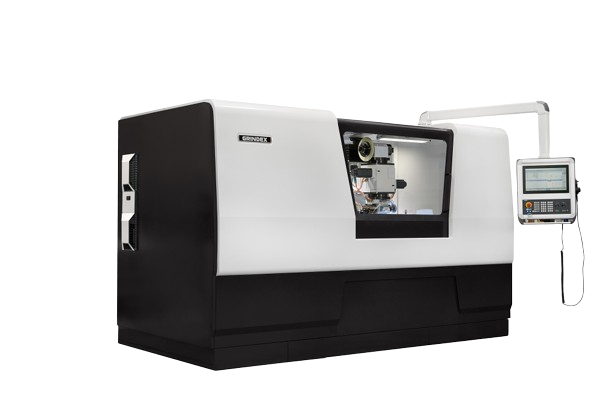

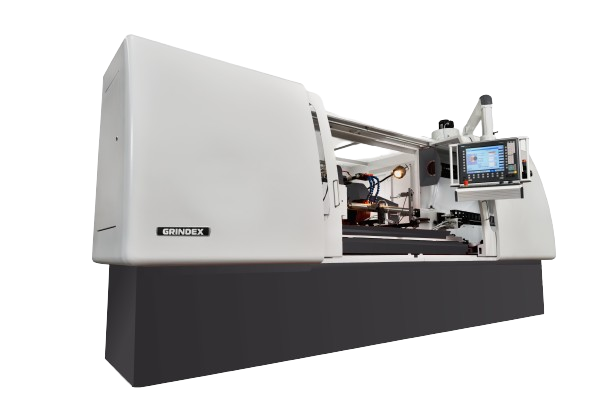

BSC Model

ABOUT MACHINE

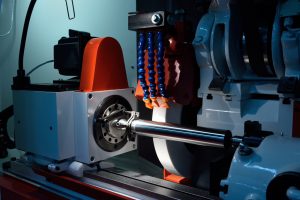

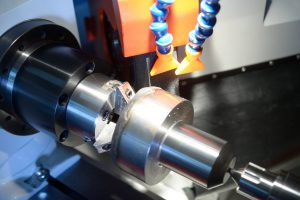

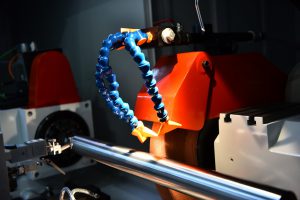

“BSC” model is universal cylindrical grinding machine for external and internal grinding of work parts medium dimensions. It is suitable for flexible and mass production. The model classification is done based on distance between centers – 700, 1000, 1500, 2000 mm. The standard swing over diameter is 350 mm, part weight up to 300 kg, while in configuration with B-axis the swing over diameter is raised to 450 mm. The maximum external grinding wheel diameter is Ø500 mm, while maximum internal grinding diameter is Ø200 mm.

The model is available in NC and CNC option. NC option has a possibility of mounting lifting type internal grinding attachment and belt driven spindle. Basic customization is related to turret wheelhead – B-Axis, with additional equipment according to the grinding requirement, primary in one set up: external grinding, hole, face, taper, complex profiles. A combination of spindles for external and high-frequency spindles for internal grinding.

ADDITIONAL OPTIONS

- Workhead equipped with C-Axis for grinding of polygons and metric threads

- Workhead make with increased accuracy

- Hydrostatic and hydrodynamic bearing support

- Various choice for wheelhead configuration – different combination of grinding spindles

- Spindle installation of increased power and torque

- FINILIFT system with air cushions for easier movement of workhead and tailstock

- Special tooling for clamping related to different technical tasks

- Manual and automatic steady rests with retractable arms and fine adjustment

- Gap-crash system for collision control and higher safety

- In-process, Post-Process gauging, touch probe for part axial positioning

- Automatic loading / unloading using robot or portal manipulator

- Remote diagnostic for immediate support and quick service

- Machine compatibility with Industry 4.0

| Technical data | BSC 700 | BSC 1000 | |||||||

| Distance between centers | 700 mm | 1000 mm | |||||||

| Center height | 175/225 mm | 175/225 mm | |||||||

| Max. workpart weight (between centers/chuck) | 300/100 kg | 300/100 kg | |||||||

| X-axis – Wheelslide | |||||||||

| Max. travel | 180/300/380 mm | 180/300/380 mm | |||||||

| Max. speed | 10000 mm/min | 10000 mm/min | |||||||

| Linear scale resolution | 0,0001 mm | 0,0001 mm | |||||||

| Servo motor power | 2,29 kW/11 Nm | 2,29 kW/11 Nm | |||||||

| Z-axis – Table movement | |||||||||

| Max. travel | 780 mm | 1150 mm | |||||||

| Max. speed | 10000 mm/min | 10000 mm/min | |||||||

| Linear scale resolution | 0,0001 mm | 0,0001 mm | |||||||

| Servo motor power | 2,29 kW/11 Nm | 2,29 kW/11 Nm | |||||||

| Max. table swiveling | 9° | 7° | |||||||

| Wheelhead | |||||||||

| Max. wheel dimensions | ø500x100xø203 mm | ø500x100xø203 mm | |||||||

| Wheel peripheral speed | 50 m/s | 50 m/s | |||||||

| Swiveling range | ±45° | ±45° | |||||||

| Motor power | 7,5 kW | 7,5 kW | |||||||

| Workhead | |||||||||

| Speed range | 0,1-500 rpm | 0,1-500 rpm | |||||||

| Spindle bore | 38 mm | 38 mm | |||||||

| Fitting taper | MT5 | MT5 | |||||||

| Swiveling range | 0°-90° | 0°-90° | |||||||

| Servo motor power | 3,3 kW/16 Nm | 3,3 kW/16 Nm | |||||||

| Tailstock | |||||||||

| Opening stroke | 40 mm | 40 mm | |||||||

| Taper error correction | ±0,04 mm | ±0,04 mm | |||||||

| Fitting taper | MT4 | MT4 |

| Technical data | BSC 1500 | BSC 2000 | |||||||

| Distance between centers | 1500 mm | 2000 mm | |||||||

| Center height | 175/225 mm | 175/225 mm | |||||||

| Max. workpart weight (between centers/chuck) | 300/100 kg | 300/100 kg | |||||||

| X-axis – Wheelslide | |||||||||

| Max. travel | 180/300/380 mm | 180/300/380 mm | |||||||

| Max. speed | 10000 mm/min | 10000 mm/min | |||||||

| Linear scale resolution | 0,0001 mm | 0,0001 mm | |||||||

| Servo motor power | 2,29 kW/11 Nm | 2,29 kW/11 Nm | |||||||

| Z-axis – Table movement | |||||||||

| Max. travel | 1650 mm | 2150 mm | |||||||

| Max. speed | 10000 mm/min | 10000 mm/min | |||||||

| Linear scale resolution | 0,0001 mm | 0,0001 mm | |||||||

| Servo motor power | 3,3 kW/16 Nm | 3,3 kW/16 Nm | |||||||

| Max. table swiveling | 6° | 5° | |||||||

| Wheelhead | |||||||||

| Max. wheel dimensions | ø500x100xø203 mm | ø500x100xø203 mm | |||||||

| Wheel peripheral speed | 50 m/s | 50 m/s | |||||||

| Swiveling range | ±45° | ±45° | |||||||

| Motor power | 7,5 kW | 7,5 kW | |||||||

| Workhead | |||||||||

| Speed range | 0,1-500 rpm | 0,1-500 rpm | |||||||

| Spindle bore | 38 mm | 38 mm | |||||||

| Fitting taper | MT5 | MT5 | |||||||

| Swiveling range | 0°-90° | 0°-90° | |||||||

| Servo motor power | 3,3 kW/16 Nm | 3,3 kW/16 Nm | |||||||

| Tailstock | |||||||||

| Opening stroke | 40 mm | 40 mm | |||||||

| Taper error correction | ±0,04 mm | ±0,04 mm | |||||||

| Fitting taper | MT4 | MT4 |